Menu

Menu

You’re likely to encounter some unfamiliar terms when looking over a quote for commercial printing. Perhaps the most common being ‘digital’ vs ‘offset’ printing.

Choosing the right printing method can make all the difference when it comes to the outcome of your project. That’s why, whether you’re a long-time publisher or a small business owner, knowing the benefits of each method is essential for maximising the value of your printed materials.

Thankfully, at Worldwide, we are here to help fill in the blanks on the best commercial and corporate printing solutions. Here’s what you need to know:

Offset printing is for larger quantities and longer lead times. It’s also the preferred way to go if colour accuracy is the top priority.

If you’ve got an office or home printer, you’re probably familiar with its requirement for Cyan, Magenta, Yellow and Black ink. In offset printing, these inks are individually applied to achieve accurate colours. If your lime green logo specifically needs to be PMS368, you’ll want to print offset.

Unlike most digital printing, offset printing is typically done on a commercial-grade print press in a factory, with expert tradespeople overseeing the process. While digital printers transfer ink directly onto paper, offset printers transfer ink from a steel plate to a rubber sheet, which is then rolled onto paper.

Because there’s more manual labour involved, naturally, the process takes a little longer. Here at Worldwide, we use the gang printing method. This means multiple jobs are printed at the same time on a common sheet of very large paper, which helps to reduce our prices and wastage. While this can be more cost-effective for you, if time isn’t on your side, it might not be a suitable option.

Digital printing is for smaller runs and shorter lead times. Digital printers use a mixture of Cyan, Magenta, Yellow and Black ink simultaneously. This is often called full-colour printing or CMYK printing.

Commercial-grade digital printing technology is much more sophisticated than your regular home or office printer though. Every Worldwide Centre is equipped with industry-standard technology, producing high-definition material with a quick turnaround.

Another benefit of digital printing is personalisation. Our digital printing technology can print variable data, like a direct mail campaign with various names and addresses.

Smaller volumes and fewer set-up requirements make the process pretty speedy. While digital printing won’t be the most cost-effective option for large quantities, it’s budget-friendly for small and medium print runs.

Ideal Use

Short-run prints, personalised items

Colour Accuracy

High, with slight variations

Material Versatility

Limited to certain paper types and sizes

Customisation

Easy to customise individual prints

Set-Up Time

Minimal

Cost

Lower for short runs due

to less setup

Printing Speed

Fast turnaround time

Environmental Impact

Typically less waste

Detail and Resolution

High resolution and detail

Ideal Use

Large-volume orders

Colour Accuracy

Very high, with consistent results

Material Versatility

Can print on a wide range of substrates

Customisation

Limited to plate changes

Set-Up Time

Requires more time for plate setup

Cost

Cost-effective for large runs due to economies of scale

Printing Speed

Slower to setup, faster for ongoing runs

Environmental Impact

More waste due to plates and setup

Detail and Resolution

Extremely high detail, especially for graphics and text

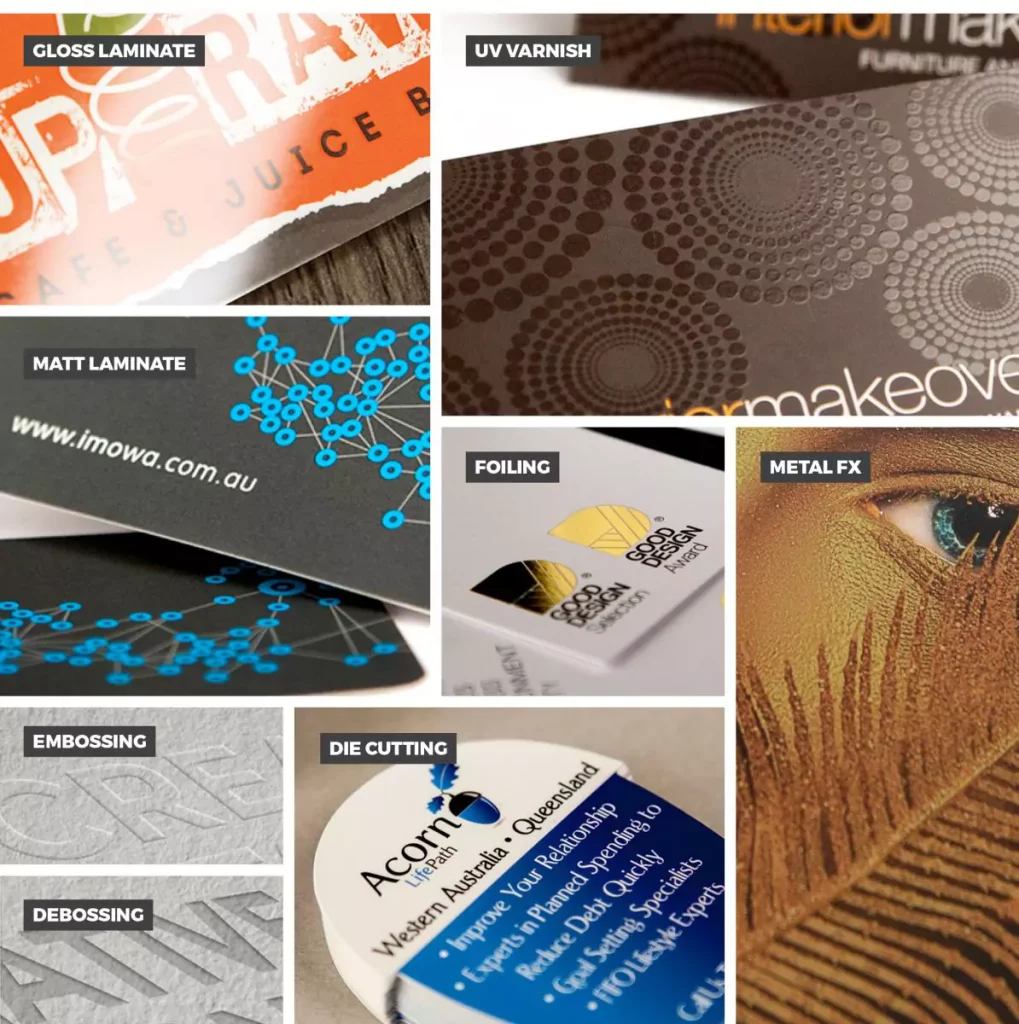

Once your digital or offset print job is hot off the press, you might wish to add a finishing touch. At Worldwide, we have a huge range of technology up our sleeves to help your print product stand out, including:

Check out our finishing effects here. Our graphic designers will design your job with printing and finishing techniques in the forefront of their minds.

Suppose you have already produced your artwork with a graphic designer. In that case, our team of print experts will make sure your artwork is set up correctly for digital or offset printing, and we can consult with you to achieve the best final product with specialised finishing techniques.

With over 25 years in the game, you’re in good hands. Contact your local Worldwide Centre for print and design experts today.

"*" indicates required fields